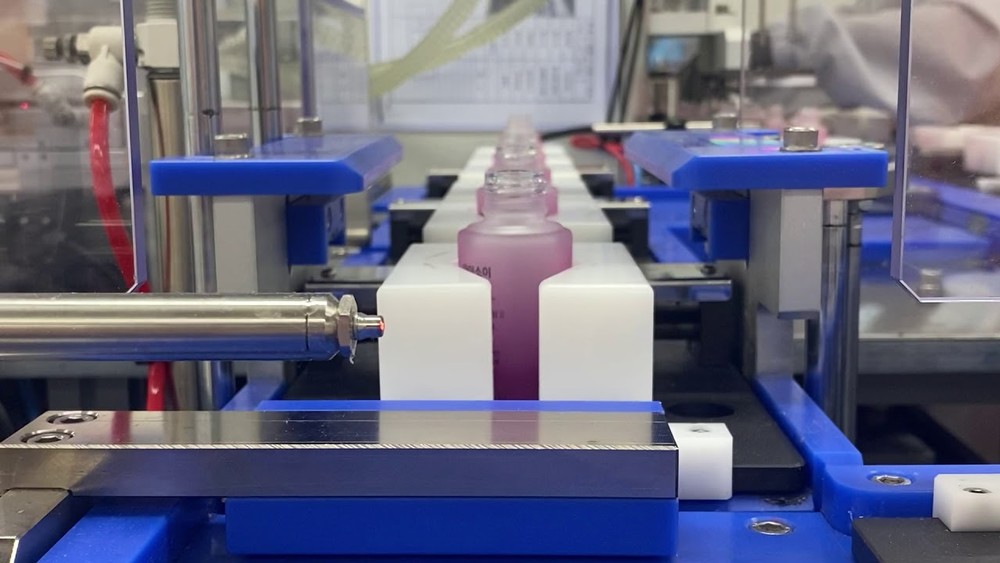

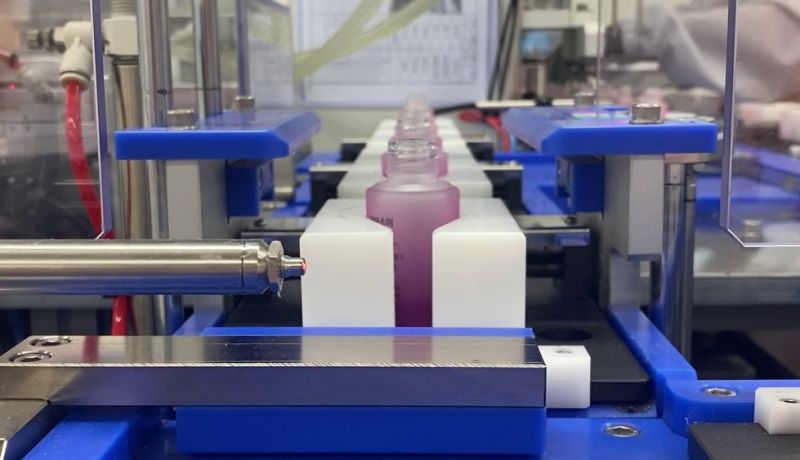

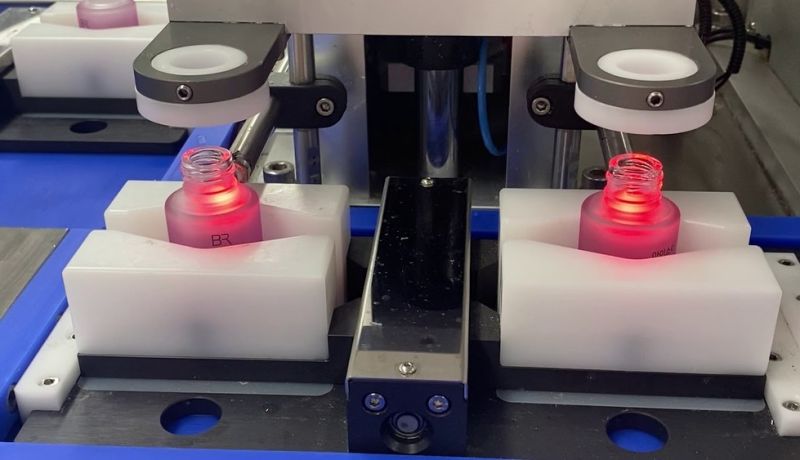

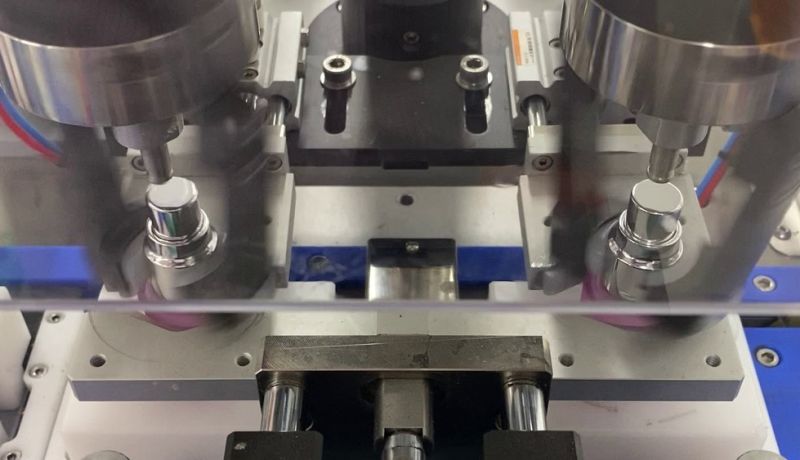

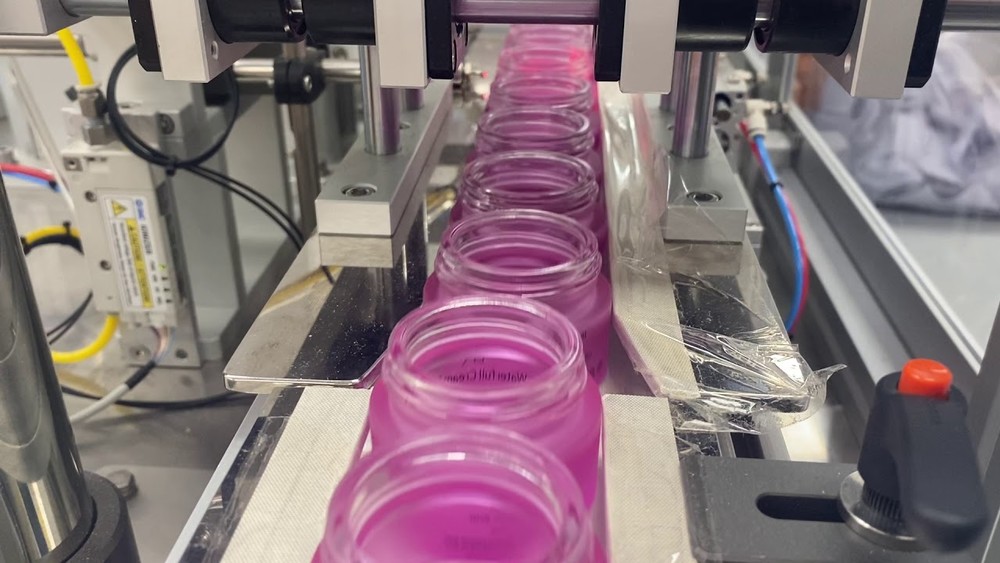

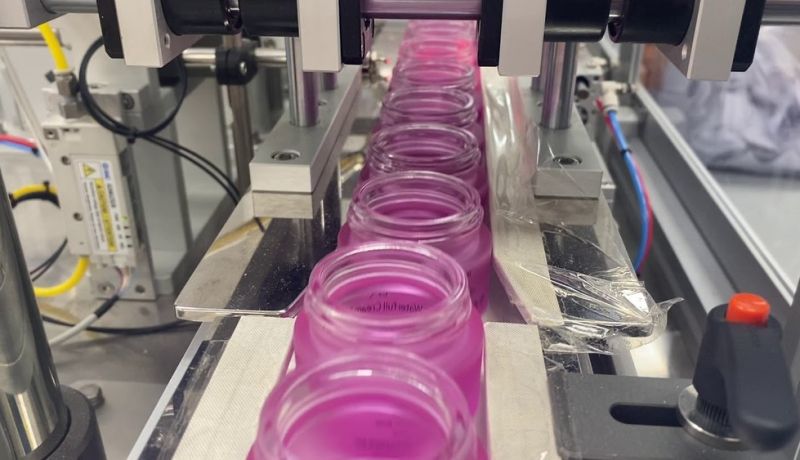

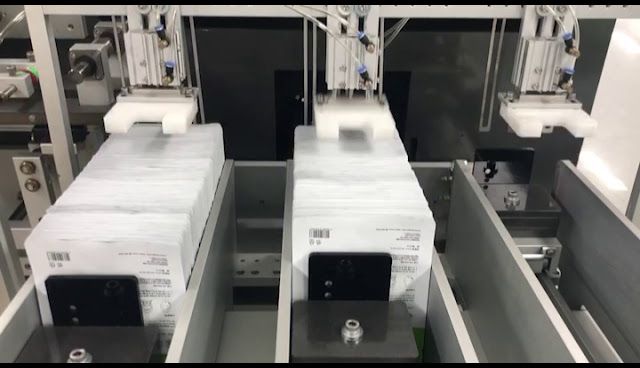

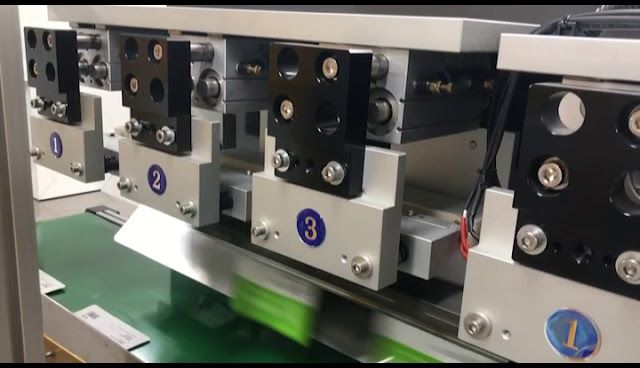

4) Multi-Cell Line Automatic Charging Facility

It is a 6-hole automatic filling facility capable of mass production, and is a more efficient production system than manual facilities, from automatic cleaning of subsidiary materials to automatic filling and capping.