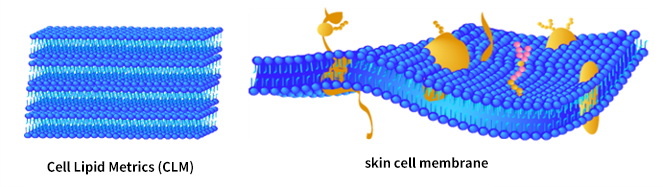

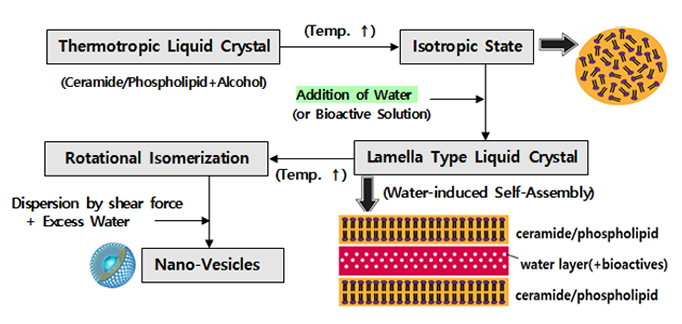

After mixing ceramide/phospholipid with alcohol in a certain ratio to make a thermotropic liquid crystal, when water is added in a certain ratio in an isotropic state at high temperature, the two lipid molecules are separated due to the difference in solvation between alcohol and water. Complex self-assembly is induced, resulting in a liquid crystalline phase with a lamella structure in which water layers and lipid layers are alternately arranged. Here, ceramide cannot form crystals due to interaction with phospholipids and is incorporated into the liquid crystal array structure. When shearing force is applied while maintaining a high temperature so that the liquid crystalline phase of the lamellar structure induced by water is in a state of rotational isomerization, the lamellar liquid crystalline phase is dispersed in water to form spherical nanovesicles.